Design office

Hexagon has a fully equipped design office with a research and development department:

- Inventor and AutoCAD used as design program.

- Simulate design operations and verify designs before issued to production for fabrication.

- Simulate stresses to designs to ensure that there are no premature failures happening at the customer.

The current layout of the factory has four operating bays:

- Bay 1 has a 5 ton double girder crane servicing the Winding bay and Flame Proofing bay.

- Bay 2 has a 5 ton double girder crane servicing the Machine bay, the Assembly bay the Final Testing and Dispatch bay.

- Bay 3 has a 5 ton double girder crane servicing the Incoming bay, Fabrication and Press Shop.

- Bay 4 has a 25 ton double girder crane.

All four cranes are remotely operated, serviced and maintained by Daytona Cranes and full records are kept.

Stripping, cleaning and assessment area

All products are disassembled, cleaned and assessed. Burn-out oven with computer control to avoid over temperatures.

The individual parts are inspected for any faults and marked for repair or part replacement.

Electrical assessment including core testing

Cores are tested for electrical properties, winding, connection etc.

The motor is tested for any electrical errors and failures.

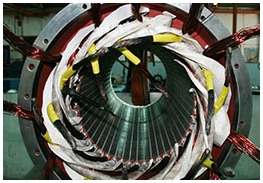

Lamination punching workshop

Full design facility designed by a Professor from the University of Witwatersrand from the Electrical Engineering Faculty.

- Hexagon manufactures rotor and stator packs for use in the mining industry, as well as a full range of pad mount flameproof motors for the ventilation market.

- Hexagon fabricates copper barred rotor for re-engineered motors and is capable to replace a die cast rotor with a copper barred rotor.

- Core and rotor punching done in-house according to electrical design for motors up to 500kW.

Hexagon has a 3.2m Guillotine with a maximum capability of cutting 6mm plate, a 3m plate roller able to roll plate size 12mm to diameter of 300mm, 4xCO2 welding machines and plasma cutting equipment.

All machining, drilling, milling etc. are done in-house. Hexagon possesses

the following equipment:

- 3x centre lathes

- 1x surface grinder for sharpening of tools

- 1x 1.5m vertical boring mill

- 1x 2.5m vertical boring mill with 2m swing

- 1x milling machine for cutting of key ways

Hexagon carries out 2 plane balancing on the Shenck machine which can balance up to 700kg at 1200rpm, including 450kW. Each unit receives an automatic print-out which is placed in a Data Book. This is issued to the customer on request. All testing is carried out in accordance with SANS 10242.

Hexagon has 6 accredited Flame Proof Inspectors carrying out patrol inspection on units being assembled in accordance with SANS 60079-0 and SANS 60079-1.

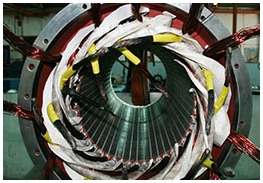

Winding department with all electrical test equipment

State of the art electrical winding design facility designed by a Professor from Wits University Electrical Engineering Faculty, which enables us to form and manufacture formed coils.

All our testing is carried out in accordance with SANS 10242 and SANS 1561 with the following equipment:

- 2x ITIG Instruments to carry out pre-varnishing testing, P.I. testing of winding and surge testing.

- Core testing and rotor bar inspection equipment with PC interface.

All instruments are calibrated at set intervals and records are traceable to an approved ATL

An Electrical Data Book is issued for each unit leaving Hexagon Electrical.

VPI Varnish tank and curing oven

Hexagon has a full V.P.I. (Vacuum Pressure Impregnation) System using a state of the art resin, with separate double dip varnishing facility.

Each unit is assembled in accordance with SANS 10242 and SANS 60079/1/15 and

SANS 60079/1/15.

Assemblers are each equipped with a full toolbox of the latest tools and trained

continually with new technology.

Hexagon has a SKF Induction Bearing Heater and a full set of fitting equipment

for fitting seals.

We test motors at full load 460kW, 6.6kV with 630kVA generator set and a complete fan test facility with conical and ventured columns. Our submersible pump test bay is capable of up to 110kW for water pumps and fans.

Hexagon possesses the following equipment:

- FAG vibration analyzer with P.C. interface

- 460kW Schenk dynamometer

- 1000kVA transformer with on load tap changer settings 0 - 650V and 0 - 3300V

- 200kVA transformer with 7 tap settings 0 - 1000V

- 200kVA transformer with 7 tap settings 0 - 500V for A.C. and D.C.

All motors, panels, cable reels, etc. are inspected for outline sizes, shaft extensions, spigot size, mounting holes, nameplates etc. For every product leaving Hexagon, an

inspection form is issued and signed off.

Units ready for dispatch are individually wrapped and painted as per customer requirements and are fitted with anti-bernelling devices and placed on pallets.

Hexagon has a fleet of vehicles ranging from

- 1x 8 ton

- 1x 4 ton

- 1x 1.5 ton

- 3x 1 ton Ranger LDV’s

Hexagon can accommodate customers without losing any time during load shedding as we have an External Power Back Up in the form of a 600kVA diesel powered Perkins Gen Set which is able to power the full facility at the click of a switch.

We can accommodate customers' certification for equipment done at Hexagon for use underground, i.e. flame proofing of complete drill rigs, as well as fitting and commissioning of equipment for use in Exd locations.

Hexagon also manufactures skids to customer requirements.

Design program

Hexagon uses the most up-to-date design program, designed by a Professor from the University of Witwatersrand, making it possible to redesign electrical motor windings to suit any application.